Introduction detail:

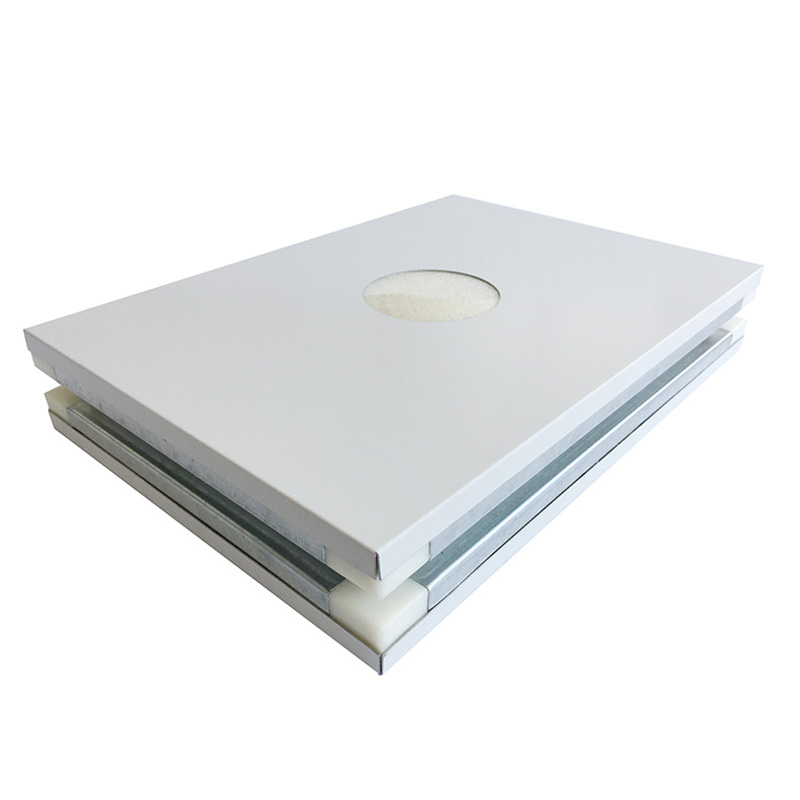

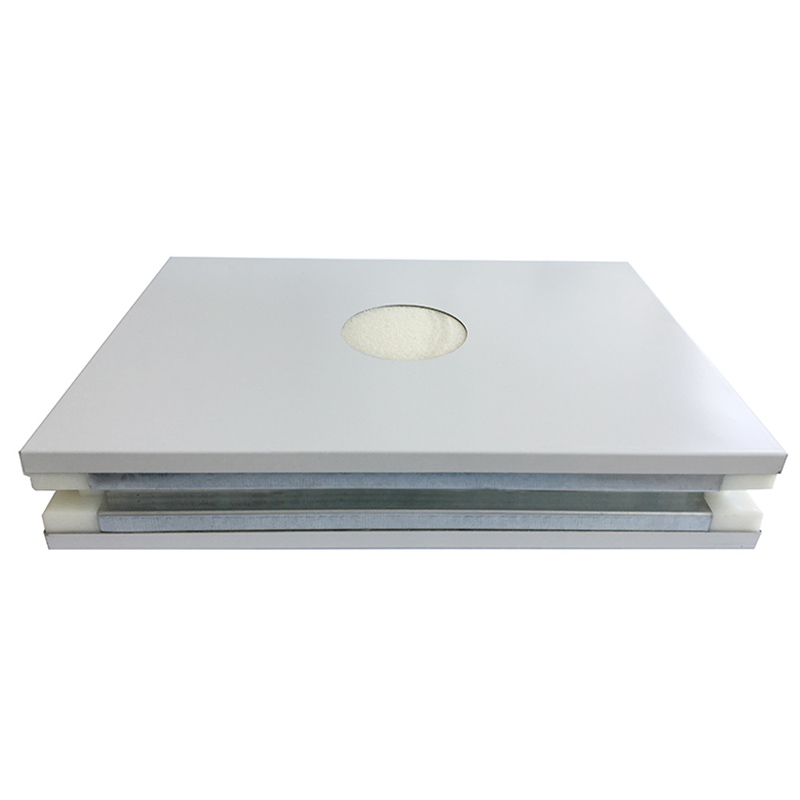

Clean room sandwich panels are main products in clean room engineering, which are flame retardant, soundproof and environmentally friendly. The Clean room panel is made up of two layers of metal panels and a functional material from the middle. It has the characteristics of easy installation, light weight and environmental protection. Moreover, the functional materials used for filling can be chosen according to different environments and production requirements. Currently, the core functional materials we can provide are: PU, PIR, Rock Wool, Aluminum Honeycomb, Paper Honeycomb, Magnesium and etc.

Classification:

Rockwool sandwich panel

Rock Wool sandwich panel are usually used for wall or ceilings that have certain requirements for fire resistance. In addition, it has very good thermal insulation properties. Most customers like the rock wool sandwich panels. Rockwool sandwich panels are commonly used in clean room engineering in electronics and pharmaceutical plants. Rock wool is a kind of inorganic fiber board which is made of basalt as the main raw material and melted at high temperature. Rock wool board is a new type of heat preservation, flame insulation and sound absorption material.

The artificial inorganic fiber processed by high temperature melting of rock wool board has the characteristics of light weight, small thermal conductivity, heat absorption and non-combustibility.

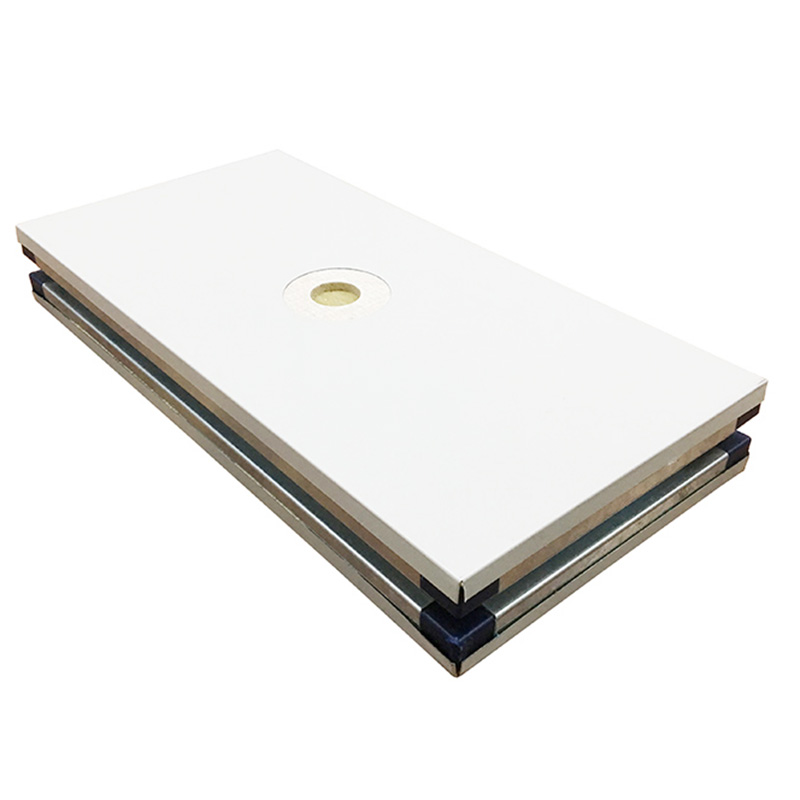

The detail of Rockwool sandwich panel:

Request for Quotation

Request for Quotation