|

Product Overview

|

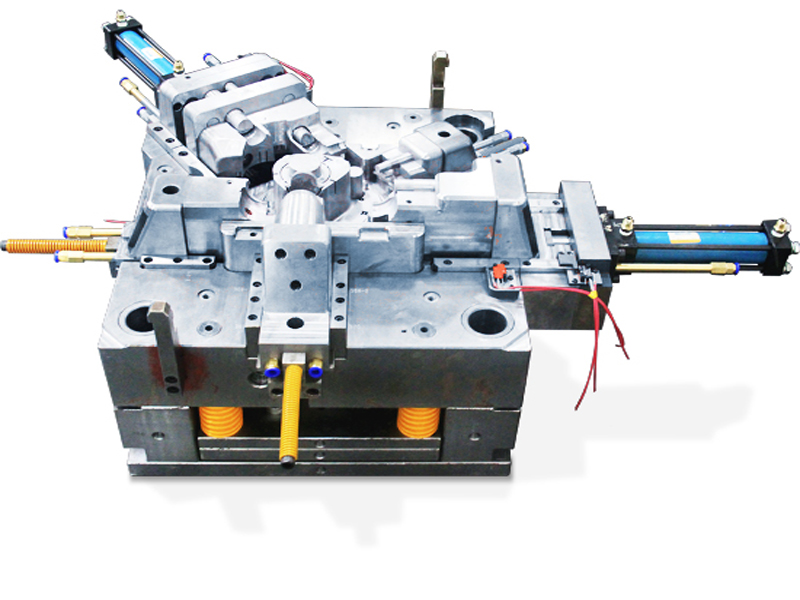

Product Name: Precision Injection Mold for PP Case with multi slider

Production Introduction: This PP Case is made with multi slider, and the mold fitting is very good, without many adjustments. Customers are very happy about the quality upon receiving T0 samples.

M old steel: S136

No. of cavities: 1*1

Part Material: PP

Mold Base: LKM/HASCO/DME

Surface treatment: Texture/High Glossy/polishing

Runner: Hot runner, from Hasco

Part Tolerance: 0.01

Shaping mode: Plastic Injection Molding

Mold lifetime: 100,000~1,000,000 shots

|

Trade Information

|

MOQ: 1 set

Mold lead time: 3~7 weeks for T1

Production lead time:2~5 weeks, according to order qty

Mold payment terms: 50% deposit by T/T against PO, balance by T/T after approval of samples but before shipment

Products payment terms: 30% deposit by T/T against PO, balance by T/T before shipment

Port of loading: Xiamen or other China port, as per customers' requirements

|

Product Image

|

|

Our Services

|

QQS Moulds provides services of plastic part design, prototype making, mold design, mold production, mass production in house. Moreover, we have reliable partner for painting, PCBA making and final assembly. We are working with many clients both home and abroad, and we keep every process very transparent with customers, because we hope to have a win-win situation for both parties.

|

Our Equipment

|

|

Our Certificates

|

|

FAQs

|

Q: Is the mold made with mechanical slider or cylinder?

A: The sliding system is with cylinders.

Q: Do you have injection machine to produce the parts?

A: Yes, we have our own injection shop, so we can make the production & assembling for customers, if request.

Q: What kind of molds are you making?

A: We mainly make plastic injection molds, but we can also build compression molds (for UF or SMC material) & die casting molds.

Q: How long does it take to build a mold?

Q: Is it possible for us to know the schedule of molds without visiting your factory?

Q: How do you guarantee the quality?

A : Nous nommerons un chef de projet pour suivre vos moules, qui est responsable de chaque processus. En plus de cela, nous avons un contrôle qualité pour chaque procédure, et nous aurons également un système d'inspection CMM et en ligne pour garantir que tous les composants respectent la tolérance.

Q : Soutenez-vous les OEM ?

Q : Avec quel type de résine procédez-vous ?

Request for Quotation

Request for Quotation